The British Summer Exchange Program is one of the formed overseas learning exchange programs of the School of Materials and Engineering since 2017, aiming to expand students’ international horizons and improve their overall quality and competitiveness. In July 2019, 14 undergraduates from the 2019 British Summer Exchange Program, led by three teachers, Li Xiang, Wu Chen and Zhu Hang, made an exchange visit to the United Kingdom. The exchange visited top universities such as Cambridge University, Oxford University, University College London and King's College London, as well as MINI Oxford plant.

Early in the morning, we set out for University College London. Professor Huang, who teaches here, kindly led us into the conference room and delivered a wonderful presentation. Professor Huang first gave a brief introduction to the school's history, famous alumni, and vision for the future. Then Professor Huang talked about his own research on new alternatives to hydroxyphosphate, biocomposite and nanocomposites, and briefly analyzed the research methods. Professor Huang also brought two doctoral students to explain the research case, let us feel the charm of scientific research.

Thinking of Xu Zhimo's poem Farewell Cambridge, with admiration for Cambridge University, we drove to visit Cambridge University. Feel the history of the six bridges, such as the math bridge, sigh bridge, feel the academic atmosphere of seven famous colleges such as T31 College, King's College, more and more feel that all the success is from tireless efforts and running.

We then made an exchange visit to the Centre for Oral Clinical and Translational Sciences at King's College London. Arriving at the College of Dental Oral and Craniofacial Sciences, we found that it was fully integrated with a dental hospital. Focusing on the connection between discipline and social needs makes research more purposeful, practical, efficient, and perhaps one of the secrets of a school's enduring life.

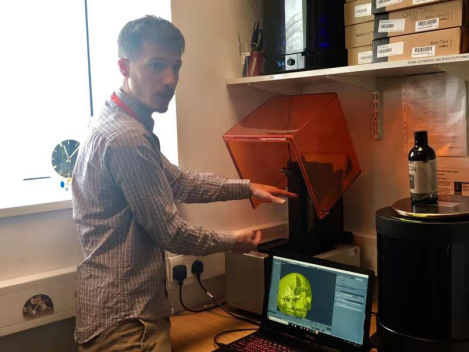

Professor David Bartlett, head of the research centre, really welcomed us, and Professor Lucy, consultant Coward, lecturer Patel and lecturer Veschini warmly received us in the conference room. We then visited three laboratories, led by Patel and two doctoral students. The approachable Patel introduced us to the functional uses of various experimental instruments, using the eyes and nose as an example to briefly explain how to repair damage and regeneratecells; Dr. Francois patiently showed us how stem cell technology and customized chip lab equipment can be used to study blood vessel formation and maturation; and another doctoral student shared how to use the latest technology, including 3D printers, to enhance their expertise and develop treatments.

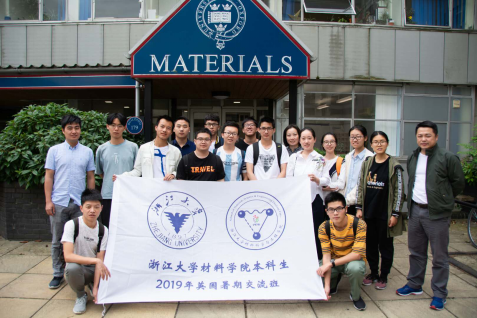

We also went to Oxford University's Department of Materials, sitting around the big lawn to interact with excellent school elders. At first everyone was a little reserved, but then the atmosphere became more relaxed. Many interesting questions were asked, the school elder is also patient to answer, and the teacher is also listening to the students' questions and give answers. The school's elder talked about which area of interest can start preparing as early as possible, and to gain a broader horizon abroad, a wealth of knowledge, different ways of thinking and access to excellent people. The teacher added that we are still in the undergraduate stage, there is confusion is normal, but we must maintain confidence in the materials major, solid foundation, and try to use the shortest time to get the fastest growth. It was a day when life planning became clearer.

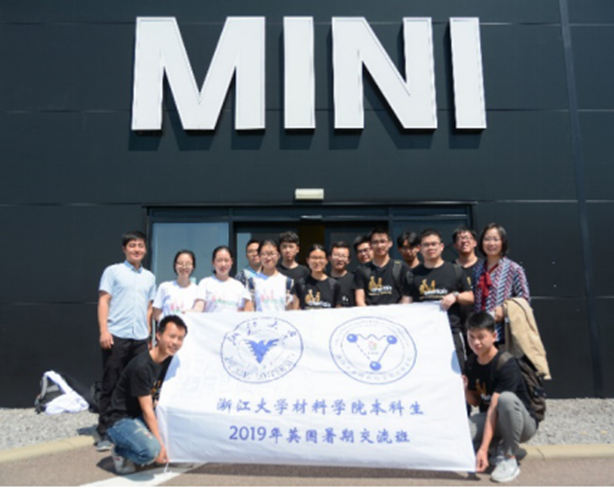

Next, we visited the MINI Oxford plant. Wearing protective clothing, eye goggles, we conduct a serious visit to the production workshop under the leadership of the staff. We first entered the body manufacturing workshop. Staff introduced that a MINI model needs spot welding 4,000 to 6,000 places, welding using eight robots in three different horizontal lines for a body work, can improve efficiency. There are 1,000 robots in the shop floor, with an automation rate of almost 100%, andstaff arerarely seen throughout the workshop. Sensors and cameras are installed on each robot to detect body errors, and sensors can be up to 0.05mm accurate.

Then we went into the assembly workshop. The body is transported to the assembly workshop for assembly of interior lines, doors and windows, engines and wheels. The automation rate of this workshop is also quite high, to the installation of the instrument table, for example, the instrument platform through the AGV transporter can quickly reach the corresponding station, the installation of the entire instrument module is completed by the power equipment. At the end of the assembly workshop, a brand new MINI car ran up and running on the ground, and our exchange visit was nearing completion.

This summer exchange activity further deepened the friendship between Zhejiang University Materials College and famous British universities and enterprises, and laid a solid foundation for more and more extensive scientific research cooperation and joint training of talents. Students who participate in exchange visits in the process fully feel the atmosphere of famous schools, with the world's top materials scientific research unit personnel to communicate, not only improve the ability to communicate and express, expand their horizons, but also enrich the experience, life has a clearer plan. At the same time, we also saw the British famous school rigorous scientific research style, novel research topics, see their own distance from the world's first-class universities and first-class materials disciplines, the future will face up to the gap, forge ahead, and strive for the early realization of the double-first-class ambitious construction goals!

Figure / Zhao Xitong and Lou Xianhui

Text / Wang Xi